FURLING MAINSAILS

If you want to make mainsail handling as easy as possible, furling is the answer. And that applies whether you have an in-mast system or one that’s fitted behind the mast. A fully-battened conventional sail with lazyjacks and a Packway will be ideal for many people, but furling provides the ultimate in convenience and control from the cockpit.

Should you decide furling is for you, that is something we will be happy to discuss with you, to ensure you are making the best choice. The most suitable type of sail will be determined by your rig, your budget and your style of sailing. So let’s consider the factors that will influence your choice.

WHAT TYPE OF MAST DO YOU HAVE?

If you have an in mast rig by Selden (or Formula, found only on bigger boats), all the options are open: You can have a sail with full-length battens, short battens or no battens. On the other hand, masts from most of the French and European manufacturers including Spacraft, Isomat and Z-Spars will give you a more limited choice. The reason is that Selden use a mandrel (the furling spar inside the mast) that is tensioned independently of the halyard and has its own top swivel. This keeps the mandrel tighter, leading to a neater furl and making better use of the space inside the mast.

Other manufacturers’ mandrels are tensioned by the halyard, whose swivel acts as the top bearing. Consequently the mandrel moves around more within the in-mast cavity, leaving less space for the sail. In addition, Z-Spars have a narrower slot in the back of the mast. What this all means is that unless you have a Selden (or Formula) mast, there will be no room for battens. This will also apply if you have an Easyreef, Tabb, Bamar, the old Reefin’ by Kemp/Selden or our favourite, Facnor.

WHAT TYPE OF BATTENS DO YOU WANT?

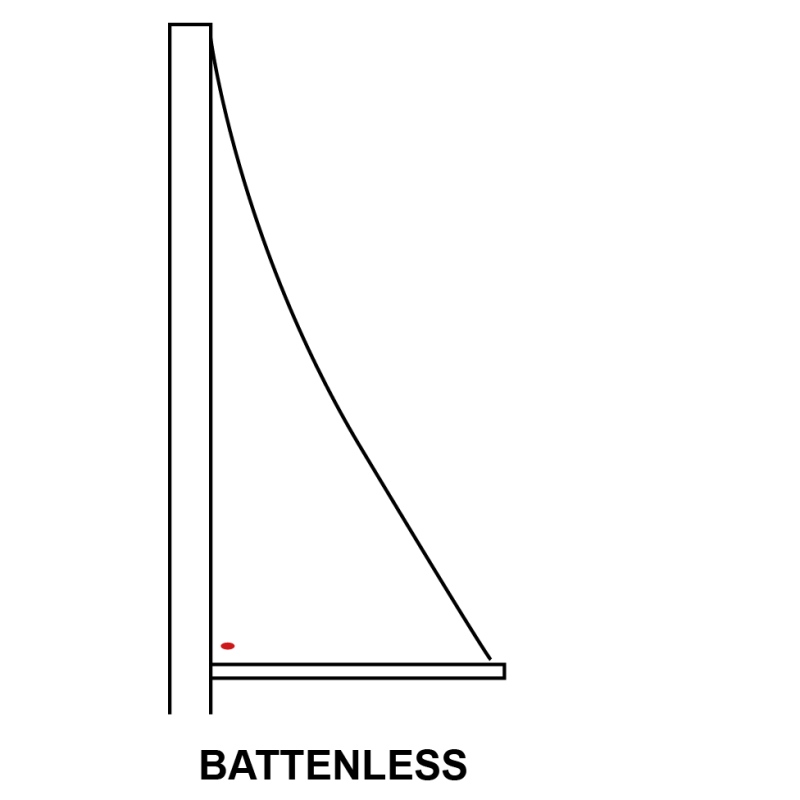

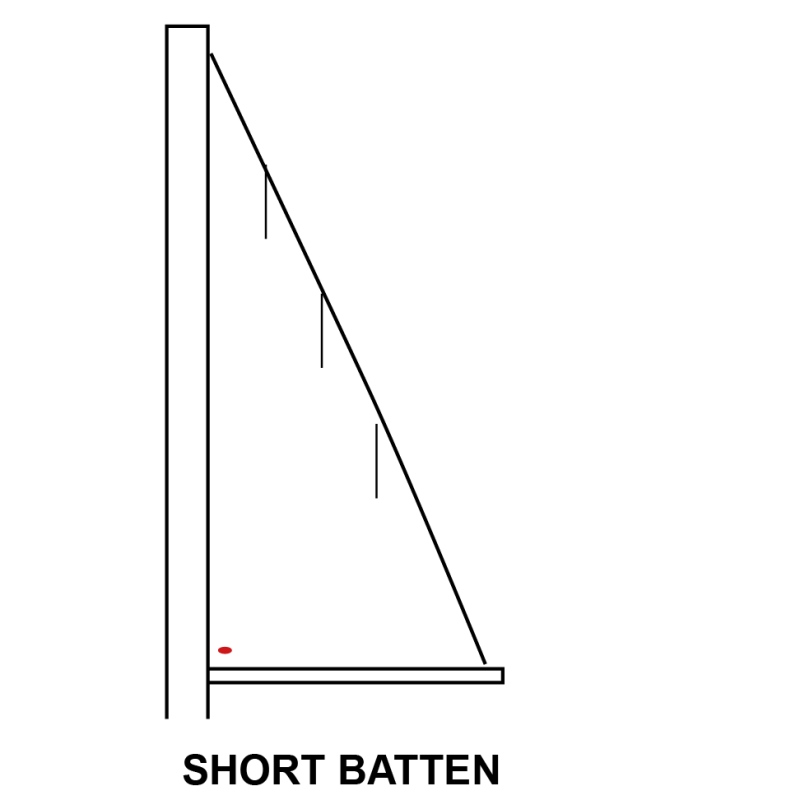

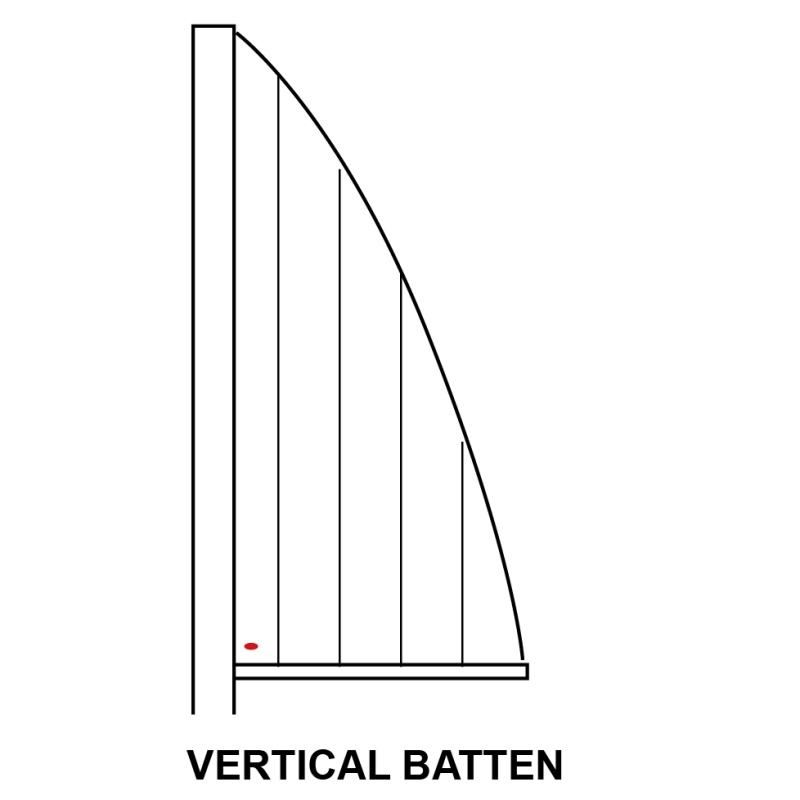

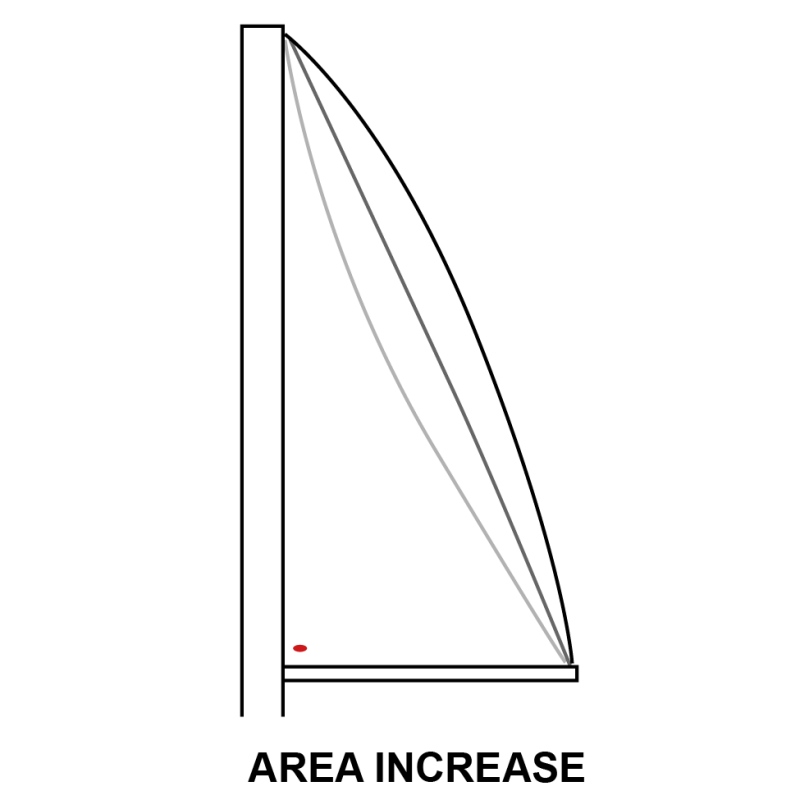

In recent years, furling mainsails with full-length vertical battens have become increasingly popular. Full battens allow the sail to be built with a roach, whereas sails with no battens have to have a hollow (concave) leech. The difference can be appreciable, a full-batten sail can be up to 6% larger than a hollow leech alternative whilst minimising any loss in performance compared with a conventional mainsail.

There are buts, however. One is that you can only have full length battens with certain types of mast, as discussed above. This means short battens are a compromise between full-length battens and no battens in terms of performance and price, but you need to check their mast compatibility with us before purchase.

WHAT CLOTHS DO WE USE?

Sails with full-length battens cost more because of the battens, they also cost more because they need to be built from a cloth that is stable, most critically in the leech, to keep the battens in alignment and rolling in and our the furler smoothly. A stable leech is also needed for both the short battened and battenless furling mainsails.

We believe that the best cloth for furling is Vectron. Due to the mix of polyester and Vectran (a multi-filament yarn spun from liquid crystal polymer), it is a strong, light and durable choice. The alternative to Vectron is a finely woven, high tenacity polyester that uses a minimal amount of stabilising resin. The upgrade to a polyester that uses minimal resin will reduce the breakdown in the stability of your cloth and therefore increase the lifespan of your furling mainsail.

As for the use of laminates in the construction of furling mainsails, many are unsuitable due to the cloths vulnerability to UV damage and that is no good when sun can access the sail through the slot in the back of the mast. Laminates are also prone to mildew build up ,which can lead to problems when a sail is left rolled up within a confined space and delamination which can increase the risk of chafing when furling and unfurling.

WHAT SETS US APART?

We apply all of our years of sailmaking experience to the manufacture of a furling mainsail.

To combat the mandrel sag within the mast, the sail needs to be built with the luff hollow (just like a headsail on a forestay), the correct amount of hollow will be determined by the profile of the mast and the type of mandrel. Un-tensioned mandrels will sag more readily in lower wind strengths, so cut your sails accordingly. Adding this design intent to our knowledge of boats allows us to ensure we are using the correct fabric for your sails. Whilst some of the French builders now have Selden rigs, a lot of Beneteaus, Jeanneaus, Gib’Seas and so on from the 1990s and early 2000s used French spars so you will be more limited to your choice of sail and cloth. Our years of experience have allowed us to gain this knowledge and apply it accordingly.

OUR CONSTRUCTION DETAILS

Building a high quality furling mainsail is about the details of construction as well as the design and choice of fabric. Here are some of the features that make our construction different from the rest:

KEVLAR REINFORCEMENT

We install specially shaped reinforcement patches at the head and clew TO help distribute the loads when your mainsail is fully open from high loads areas without adding excessive bulk. As soon as you start to reef, the patches are rolled away and all the weight is taken by the sail cloth itself. To compensate for this we incorporate Kevlar tape along the foot and leech to take the loads, on larger boats we also apply Spectra webbing along the foot for greater durability. You will not find many other sailmakers doing this.

TOUGH BATTEN POCKETS

With our full-length battens we use stainless steel sockets at the top and bottom of each pocket to stop the battens wearing their way through. We use the same system with short-batten sails on larger boats. For smaller short-batten sails, Velcro provides strength while minimising weight and bulk.

PADDED CLEW COVERS

Big sails need big clew blocks. These can damage anything they come into contact with and they’re also susceptible to UV degradation, especially on bluewater cruising yachts. That’s why, on our larger furling sails, we protect these blocks with padded covers.

FURLING INDICATORS AT THE TACK

Many boats are now fitted with electric winches, which are fine if used carefully. If you keep pressing the button when you should have stopped, something is likely to break. That’s why we put marker stripes along the foot near the tack of our larger furling sails: when they start to appear, the sail is nearly fully open and it’s time to take your finger off the button!